Cutting

The rubber comes in as a vulcanised sheet or roll. So we can immediately start producing your rubber product. The cutting of the various types of rubber, and other materials, is done using various machines:

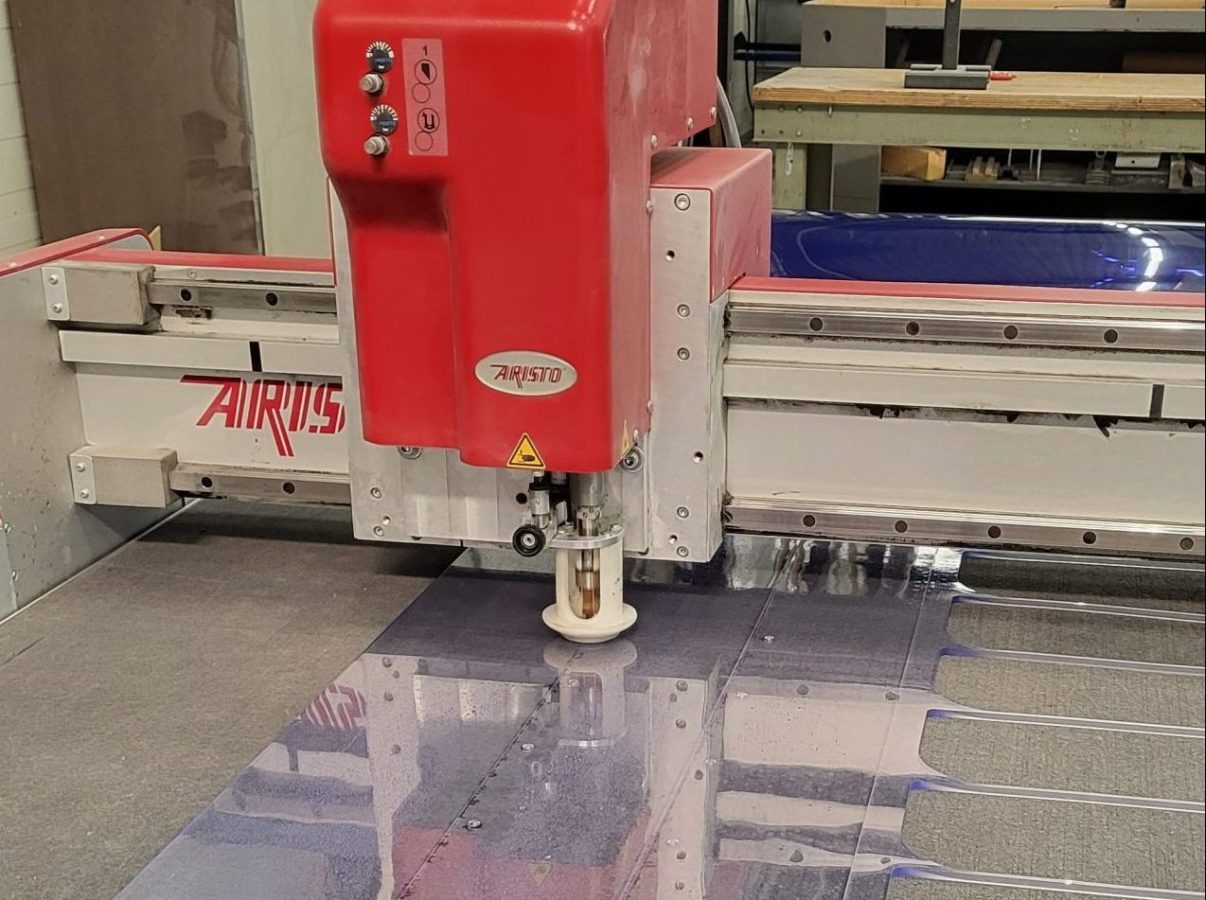

CNC cutting

Using computer-controlled machines, we can cut the most extraordinary designs and products from sheet material. Mostly rubber, but we can also cut unusual or unique shapes from graphite sheet, soft PVC or wool felt. Think in terms of a PVC cutting mat for the graphics industry, but one which has a maximum thickness capacity of 15mm. To process thicker material, we use a water-jet cutting plotter.

One of our cutting machines also has a convenient conveyor belt, which makes it possible for us to handle longer lengths as well. Very large rubber products are cut into segments which can be linked together using a dovetail joint.

Cutting a rubber product with the CNC-controlled cutting plotter only requires a digital DXF drawing. This blueprint can either be provided by you or we can produce it together. There is no need to make a separate mould or punching knife to customise the rubber product; a sharp, oscillating knife will do the job.

Cutting rubber strips

If you need rubber strips, the strip cutters of Hofland Rubber can cut strips effortlessly from rubber sheet and soft PVC. Think of rubber support components or rubber strips for the building industry. The maximum width of our largest rubber cutting machine is 1500mm, and with a thickness range from 8 to 25mm there is hardly any limit to what we can achieve for you, so feel free to contact us to learn about the possibilities.

Waterjet cutting

Using our water-jet equipment, we can cut products with the utmost precision and practically without burrs up to a thickness of 200mm. That means that this way of processing rubber can be deployed for many purposes. In common with other cutting methods, no heat is used during the water-jet cutting of rubber, so all the properties and structure of the material remain unchanged. If necessary, ultra-fine sand can be added to the powerful water jet. With a water pressure of 4000 bar, this jet effortlessly cuts through thick and hard materials

Looking for a rubber moulding article or an extrusion product? Then Hofland Rubber is the right place for you. Do you have another question about our possibilities? Please contact us. We will gladly help you on your way.